Continuous caster

With over two decades of specialized expertise in continuous casting systems and long-term technical collaboration with renowned global enterprises, we have integrated advanced technologies and built a highly skilled team of design and process engineers. To date, we have successfully provided over 100 sets of complete continuous casting equipment for carbon steel, alloy steel, stainless steel, billets, slabs, round blooms, medium and thin plates, as well as heavy and wide slabs to steel plants. We have independently handled the full cycle of continuous casting systems — from design and fabrication to installation and commissioning — delivering complete turnkey solutions for steel plants worldwide.

Core Equipment

Ladle Turret

![]() Delivered 100+ ladle turrets to worldwide clients.

Delivered 100+ ladle turrets to worldwide clients.![]() 95% market share in 450+ ton single-arm ladle turrets.

95% market share in 450+ ton single-arm ladle turrets.![]() Manufactured the world’s heaviest 530 ton unit.

Manufactured the world’s heaviest 530 ton unit.

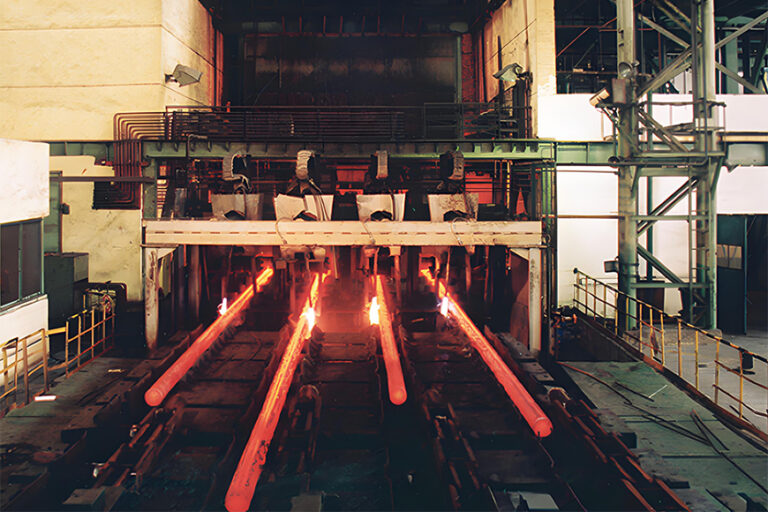

Withdrawal Straightener

![]() Multi-drive roll coordination balances billet downforce dynamically.

Multi-drive roll coordination balances billet downforce dynamically.![]() Variable frequency speed control system controls pulling speed.

Variable frequency speed control system controls pulling speed.![]() Stable casting billet transportation, low internal cracking risk.

Stable casting billet transportation, low internal cracking risk.

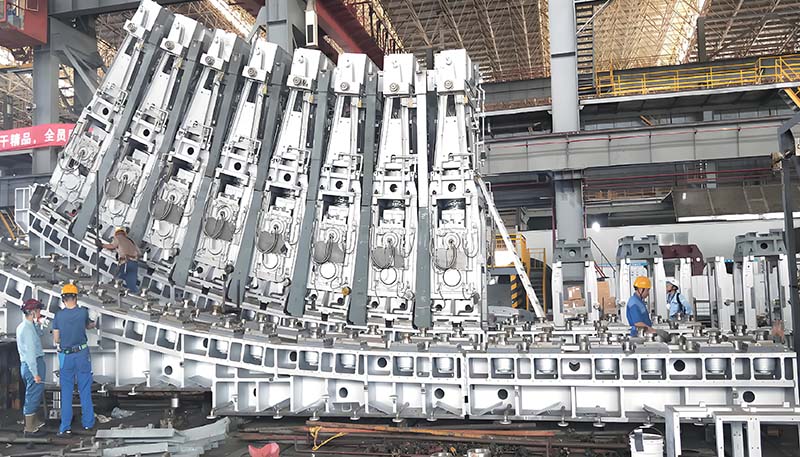

Segment

![]() Delivered 1000+ customized segments to worldwide clients.

Delivered 1000+ customized segments to worldwide clients.![]() Breakthrough support for up to 470mm heavy plate segments.

Breakthrough support for up to 470mm heavy plate segments.![]() Innovated technology of rolls, extending lifespan in prototype tests.

Innovated technology of rolls, extending lifespan in prototype tests.

Mould Assembly

![]() With high-purity pipe components and various water jacke enhance cooling efficiency, accelerate molten steel to solidify.

With high-purity pipe components and various water jacke enhance cooling efficiency, accelerate molten steel to solidify.![]() With modular framework structure, shortens assembly time, and is suitable for multi-spec production.

With modular framework structure, shortens assembly time, and is suitable for multi-spec production.