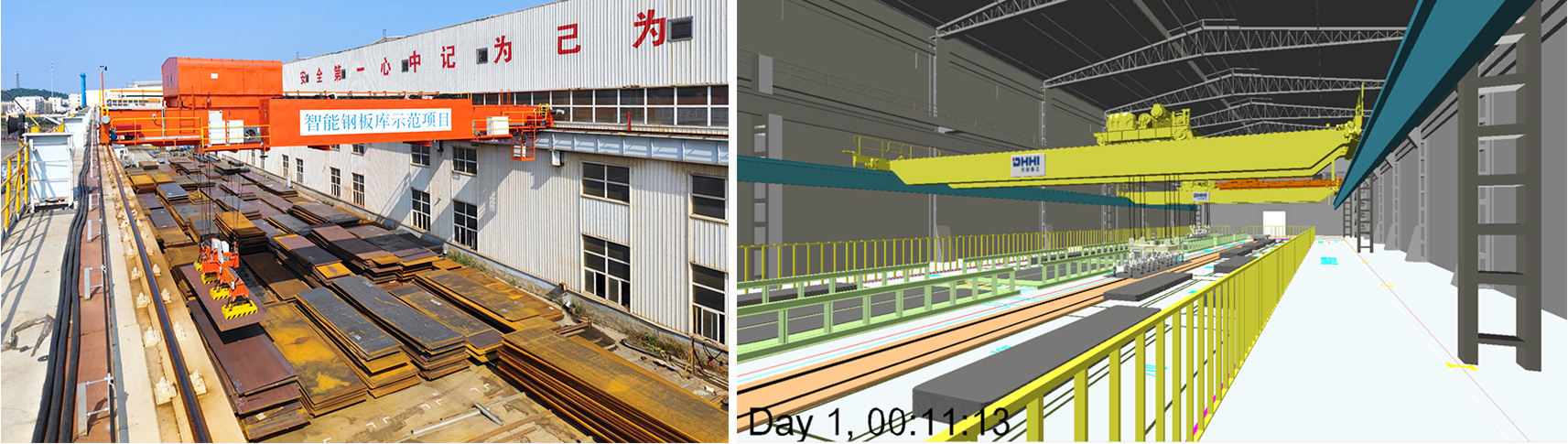

Intelligent total solution for warehousing and logistics

HDM is dedicated to the research and development of unmanned handling systems for molten steel ladles, molten iron ladles, steel coils, steel plates, billets, steel ingots, rods and wires, coal, ore, and more. The company provides customers with comprehensive solutions for subsystems and equipment, including machine vision, intelligent algorithms, fault diagnosis, longevity management, remote monitoring, operation and maintenance, as well as intelligent lifting and ground transportation equipment.

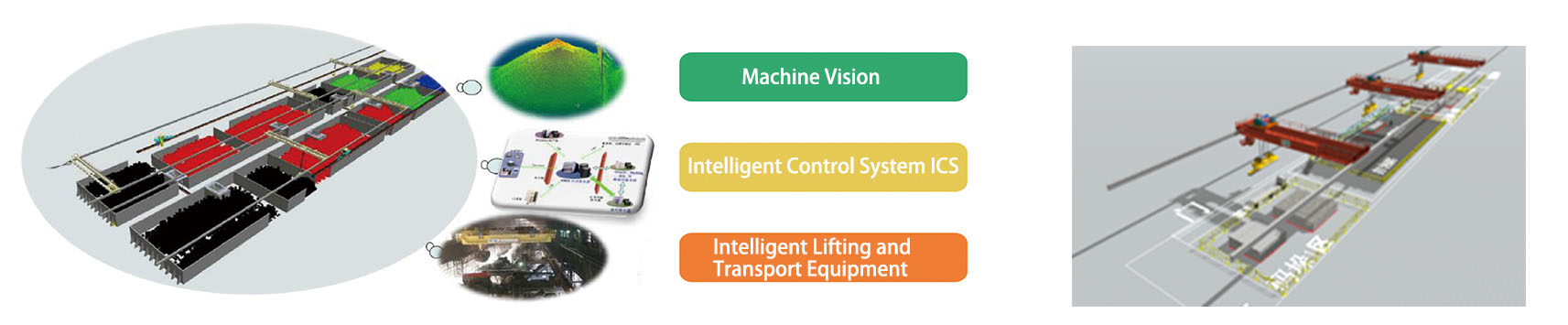

Intelligent lifting and transporting system

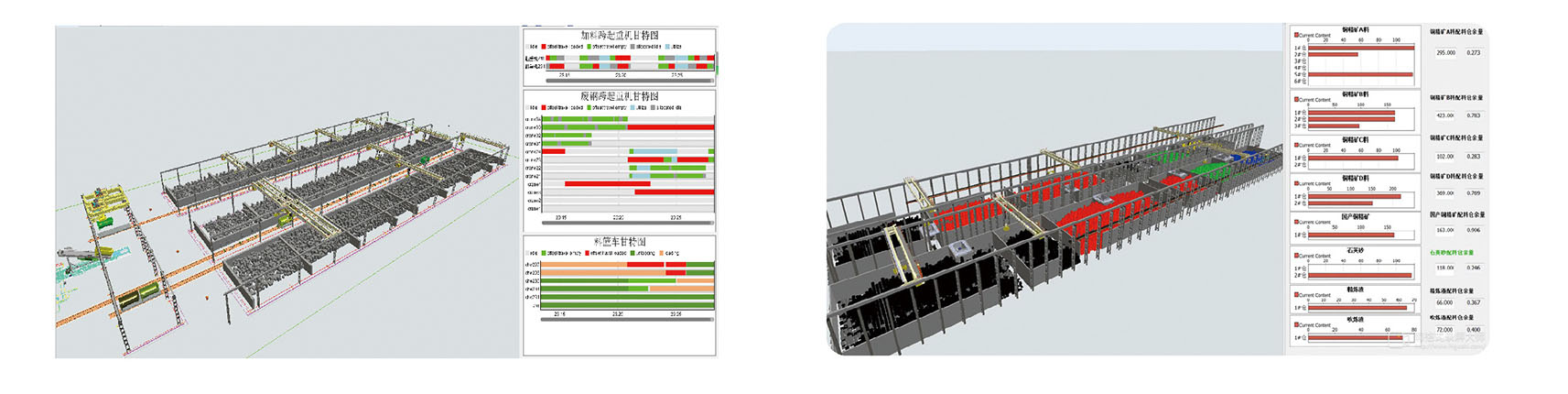

Intelligent lifting and transporting is a comprehensive solution that integrates subsystems such as storage area management, scheduling algorithms, and intelligent handling to enable perception, decision-making, and execution. This system operates based on a standard production and operation process, sensing environmental information like equipment and inventory status through position sensors and machine vision. It independently breaks down the production plan after analysis by the warehouse intelligent management system. Operating instructions are generated through intelligent scheduling and path planning technologies, allowing the intelligent equipment to complete tasks and feed results back via automatic control and precise positioning technologies. Additionally, the system includes features such as remote operation and maintenance, cloud services, and mobile push notifications to facilitate full-life-cycle management and real-time site monitoring. HDM is committed to enhancing operational efficiency and effectiveness through this advanced solution.

Effects: The efficiency of warehouse entry and exit approaches the average level of manual operations, enabling 24-hour continuous operation. The system achieves “one post with multiple functions,” resulting in a 60% reduction in personnel requirements. The utilization rate of storage capacity increases by 30%, logistics costs decrease by 20%, and the error rate is reduced by 80%. The intelligent lifting and transporting system features algorithms with independent decision-making capabilities and programmed production management logic. After receiving production tasks, it independently breaks down the plan and selects positions, lifting equipment, and transporting equipment based on the warehouse entry and exit strategy, facilitating intelligent scheduling of the equipment. The logistics simulation system utilizes transport capacity analysis to quickly implement intelligent logic, identify production bottlenecks, and enhance the intelligence level of the system. HDM is dedicated to optimizing warehouse operations through this advanced technology.

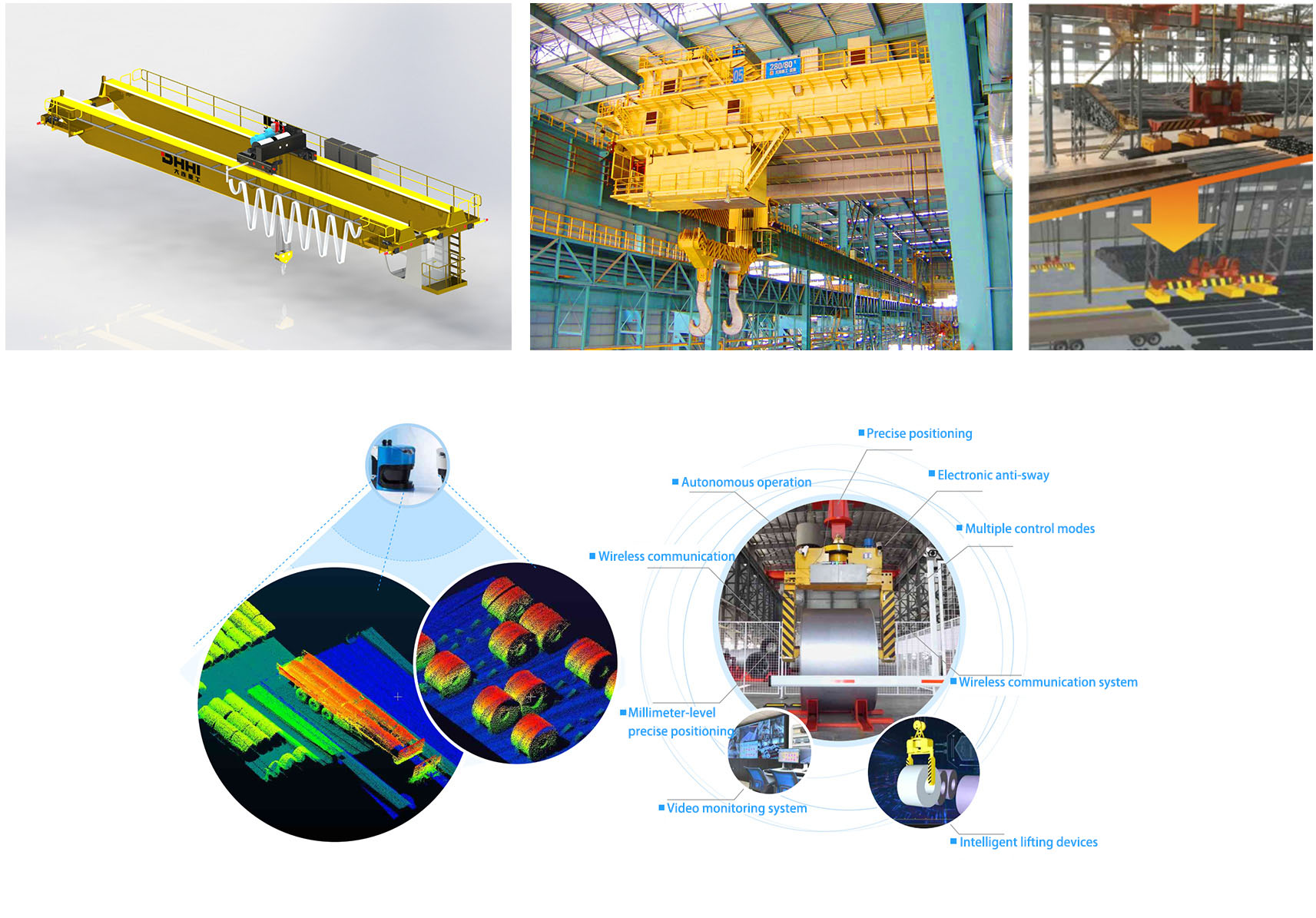

Intelligent Crane: The intelligent lifting and transporting equipment achieves independence, efficiency, and safety through an automatic control program via wireless communication to complete ICS instructions and provide feedback. This is based on machine perception technologies such as precise positioning and collaborative control technologies like electronic anti-sway. HDM is committed to advancing the capabilities of intelligent cranes for optimized operations.