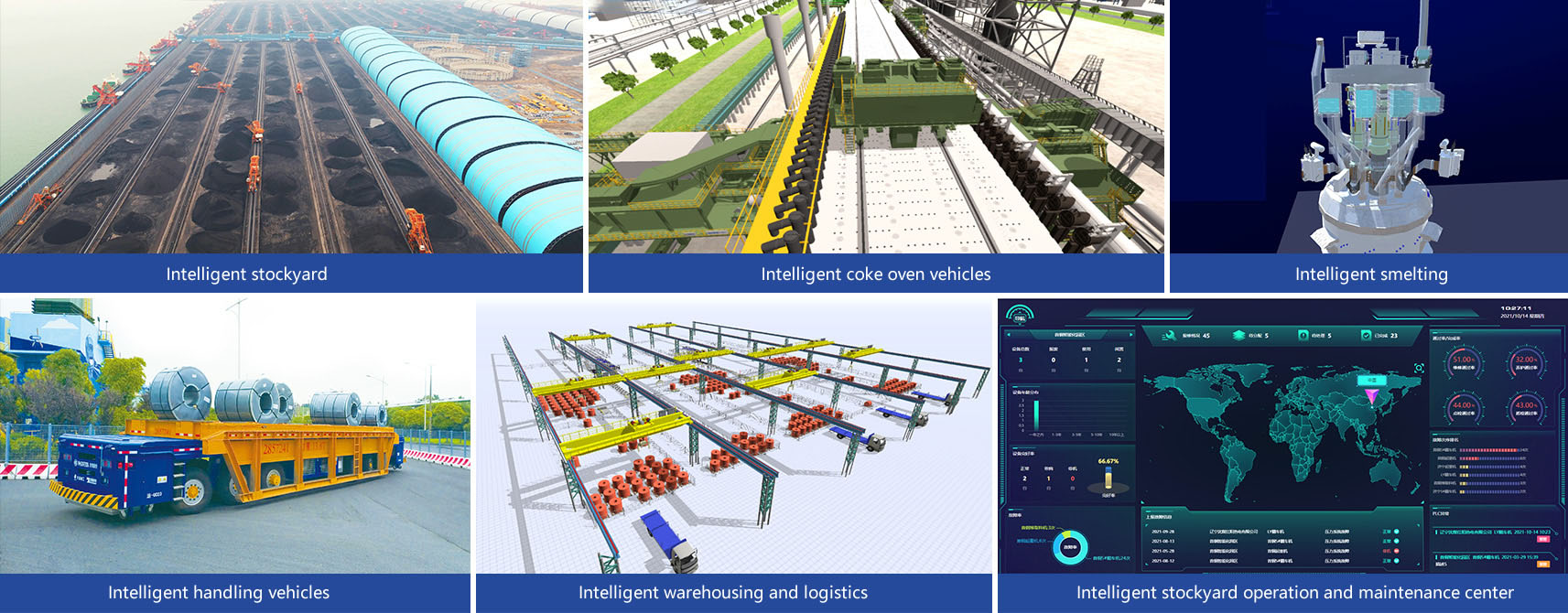

Egarding the metallurgy, port, and mining fields, HDM provides total solutions for smart ports & terminals, smart coke oven vehicles, smart warehousing and logistics, smart submerged arc furnace plants, smart handling vehicle systems, and remote smart operation and maintenance systems, etc. HDM established a specialized intelligent product R&D team of more than 200 persons, including experts in technological process, design, control, optimization, algorithm, software, etc. HDM set up an intelligent laboratory for the purpose of building a fully integrated digitalized commissioning and testing platform for heavy equipment. The combination of software and hardware realizes logic control of components and the whole machine, providing full-range assistance for site simulated commissioning, R&D, and testing of intelligent technology for heavy equipment, setting an example for performance warranty, schedule assurance, and site efficiency guarantee for key projects of HDM.

Intelligent products

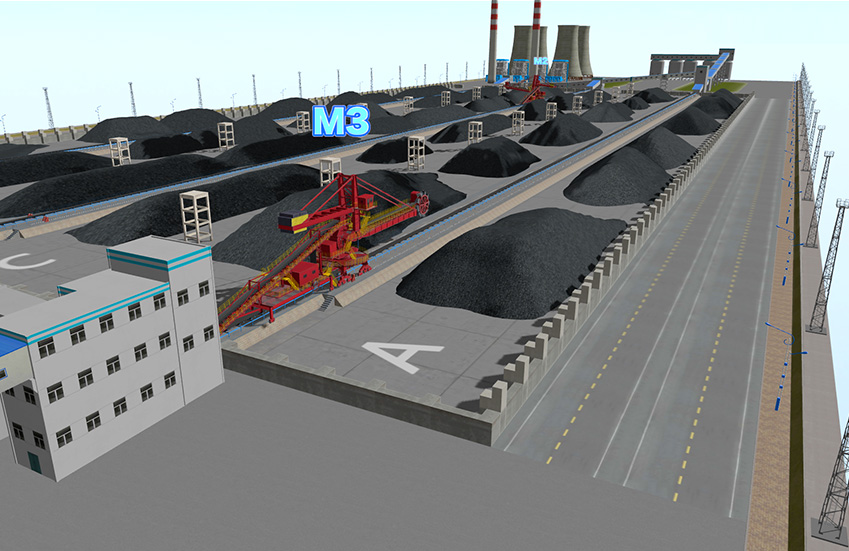

Intelligent total solution for bulk material

The total solution for bulk cargo at intelligent ports and terminals is the core of HDM’s customer service. This solution focuses on providing digital and intelligent products and services for the storage and transport of bulk materials at open/closed strip-shaped stockyards, circular yards, and terminals. The product range includes unmanned car dumpers, belt conveyors, stackers and reclaimers (boom type, scraper type, gantry type, and blending type), material unloading cars, ship loaders, and ship unloaders, among others.

Intelligent total solution for coke oven

HDM has a specialized production base for coke oven machinery. The intelligent coke oven machinery designed and manufactured allows for automatic operation in unmanned mode according to the production plan, eliminating the need for operators or on-duty personnel. It features functions such as hazard identification, intelligent decision-making, failure prevention, failure alarms, and shutdown capabilities.

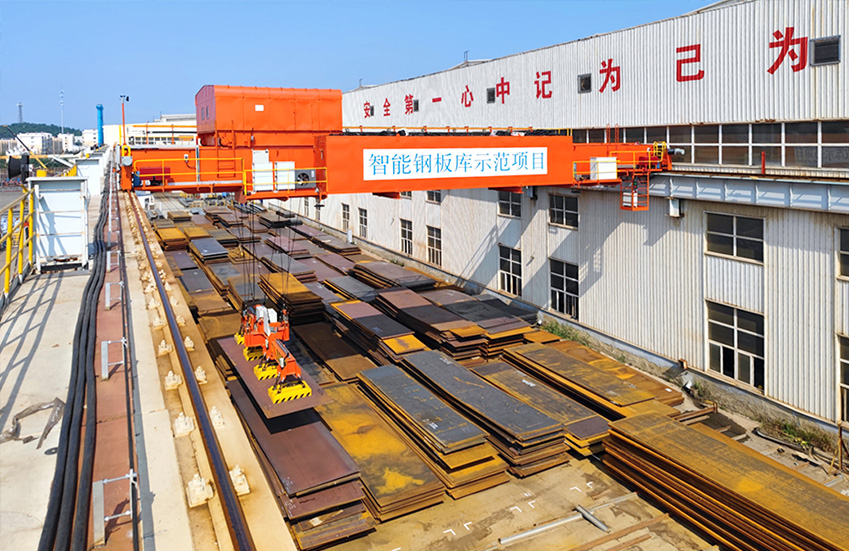

Intelligent total solution for warehousing and logistics

HDM is committed to the research and development of unmanned handling systems for molten steel ladles, molten iron ladles, steel coils, steel plates, billets, steel ingots, rods and wires, coal, ore, and more. HDM provides customers with total solutions for subsystems and equipment, including machine vision, intelligent algorithms, fault diagnosis, longevity management, remote monitoring, operation and maintenance, as well as intelligent lifting and ground transportation equipment.

Total solution for intelligent sub-merged arc furnace

HDM is a leading enterprise in the large submerged arc furnace industry in China. It drives the development of domestic submerged arc furnaces towards larger scale, energy efficiency, environmental friendliness, and intelligence. HDM holds complete core technologies for submerged arc furnaces, including process technology, control technology, and mechanical discharging technology.

Total solution for intelligent transport vehicle

The heavy-duty AGV is an intelligent transportation vehicle designed to carry heavy components, featuring functions such as self-guided operation, automatic lifting, multiple steering modes, obstacle avoidance, and collision prevention. This product supports various navigation modes, including inertial navigation, natural navigation, and laser navigation, as well as multiple power modes such as hybrid and pure electric. It also offers various drive modes, including hydraulic and electric, and control modes that allow for unmanned operation or manned remote control, with a maximum loading capacity of up to 200 tons.

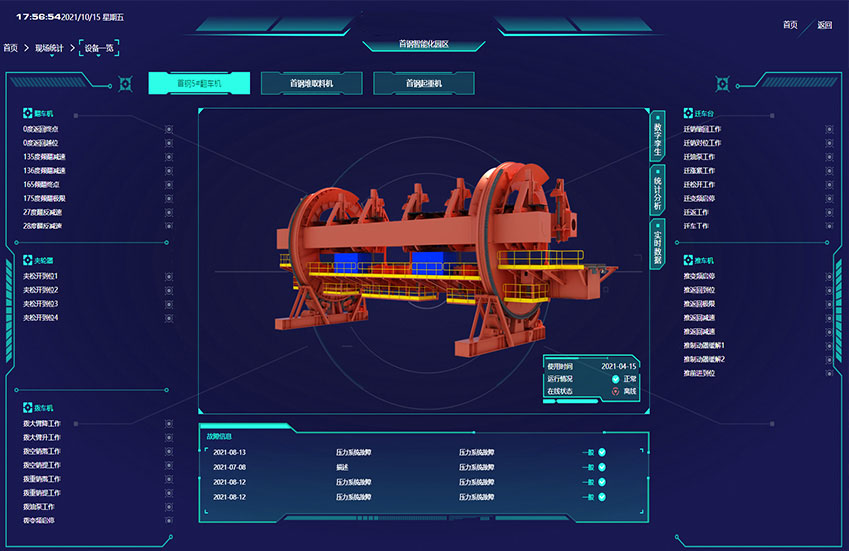

Intelligent total solution for remote operation and maintenance

Based on data analysis, HDM developed a remote intelligent operation and maintenance platform tailored to product performance and technical characteristics. This platform integrates advanced technologies such as fault diagnosis, sensor detection, digital twin technology, data analysis, data mining algorithms, and cloud computing to enable functions like fault location and the delivery of maintenance plans and suggestions.