HDM actively implements new development concepts centered on “environmental protection,” vigorously transforming toward greener practices. The company focuses on the research and development of eco-friendly products and promotes green production processes. HDM is dedicated to developing low-carbon equipment to help achieve “carbon reduction” and “carbon neutrality.” The green products developed and manufactured by HDM fall into four major categories: flue gas engineering, solid waste engineering, sewage engineering, and energy-saving engineering.

Flue gas engineering

HDM has independently researched and developed a series of dust-removal products for coke ovens, creating an integrated full-range service system from fume collection to fume management. This has provided high-quality, environmentally friendly dust-removal equipment for domestic coking and iron and steel enterprises.

The coke oven dust-removal system is utilized in the coking process of steel and coking plants to treat the smoke and dust generated during operation. It employs low-pressure pulse bag dust-removal technology, which is highly efficient, achieving dust emission concentrations that meet the ultra-low requirement of ≤10 mg/Nm³. This system is applied in steel and coking plants and is classified into machine and coke side dust removal for tamping coke ovens, as well as machine and coke side dust removal and coal charging dust removal for top-charging coke ovens.

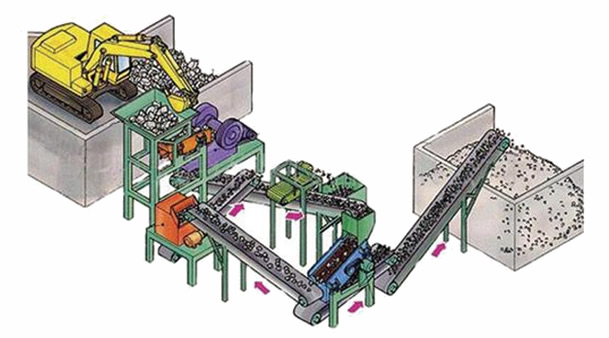

Solid waste engineering

HDM is engaged in the field of comprehensive solid waste treatment, offering EPC and investment and operation services for engineering projects related to domestic garbage and kitchen waste treatment, comprehensive disposal of sludge, hazardous waste disposal, and the comprehensive utilization of industrial solid waste.

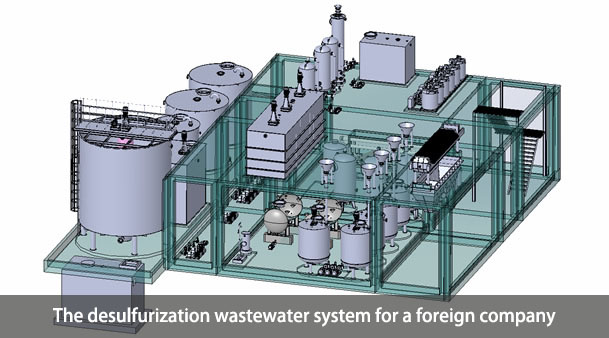

Sewage engineering

HDM has been engaged in the treatment of various types of wastewater, including coking wastewater, coal chemical wastewater, desulfurization and denitrification wastewater, zero discharge wastewater, domestic wastewater, tannery wastewater, pesticide wastewater, food processing wastewater, pharmaceutical wastewater, machining wastewater, and chemical industry wastewater. The company serves multiple sectors, such as electric power, steel, coal chemical, and petrochemical industries, through business models like EPC and BOT. HDM has extensive experience in the design, management, construction, commissioning, and operation of related projects.

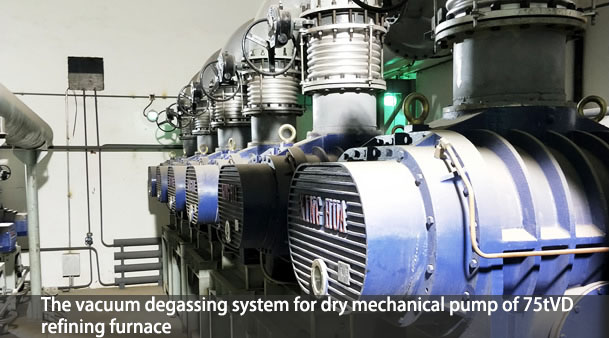

Energy-saving engineering

HDM focuses on R&D related to industrial energy saving and automation control, along with product development and service integration. In the fields of energy saving and environmental protection, HDM offers a full range of services, including engineering design, equipment supply, and engineering construction, for projects such as dry vacuum degassing systems, shore power systems, and environmentally friendly centralized control systems.