Core components for wind turbine

HDM began developing and manufacturing core components for megawatt-level wind turbines in 2004. The company has successfully developed 15 types of core components for 1.5-6MW wind turbines, including gearboxes, yaw and pitch drives, and nodular iron castings, which are now in batch production.

Detailed introduction

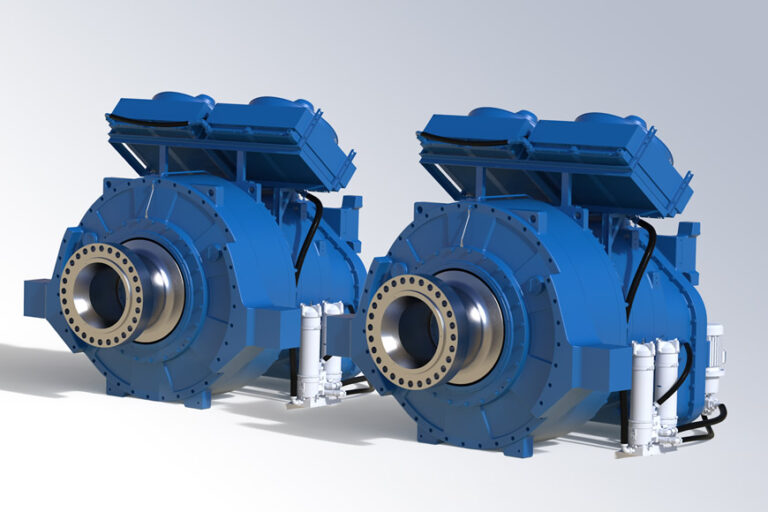

As a leading gearbox manufacturer for megawatt-level wind turbines in China, HDM has developed over 10 series of gearboxes that encompass dozens of types, with a total supply exceeding 14,000 sets. These gearboxes are widely utilized in both onshore and offshore wind sectors domestically and internationally. The series gearboxes designed for 2.X MW, 3.X MW, and 4.X MW wind turbines feature platform-based designs, enabling quick customization to meet customer demands. The products are known for their stable performance, high reliability, and are exported to regions such as the EU, South Korea, Japan, and India.

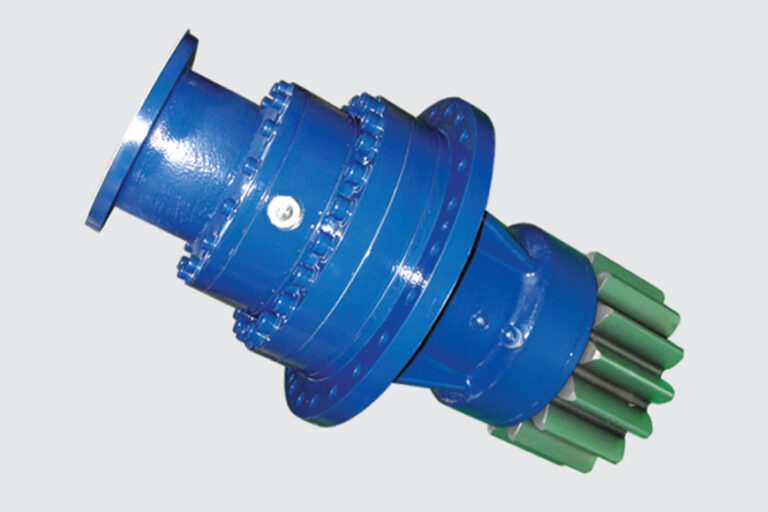

HDM has established a yaw and pitch drives development center that employs advanced international design software to create products tailored to various wind field requirements for 1-6MW wind turbines. This approach has led to modularized, serialized, and standardized production of yaw and pitch drives for different wind turbine types.

Additionally, HDM has the capacity to produce 100,000 tons of nodular iron castings for wind turbines annually. With eight casting lines, the company produces components such as hubs, elbows, and bases for wind turbines ranging from 0.85 to 12 MW. Monthly production exceeds 70 sets of castings for offshore wind turbines, and HDM has successfully developed castings for multiple wind turbine types, including those ranging from 3-4.5MW, 5-7MW, 8-10MW, and 10-12MW.