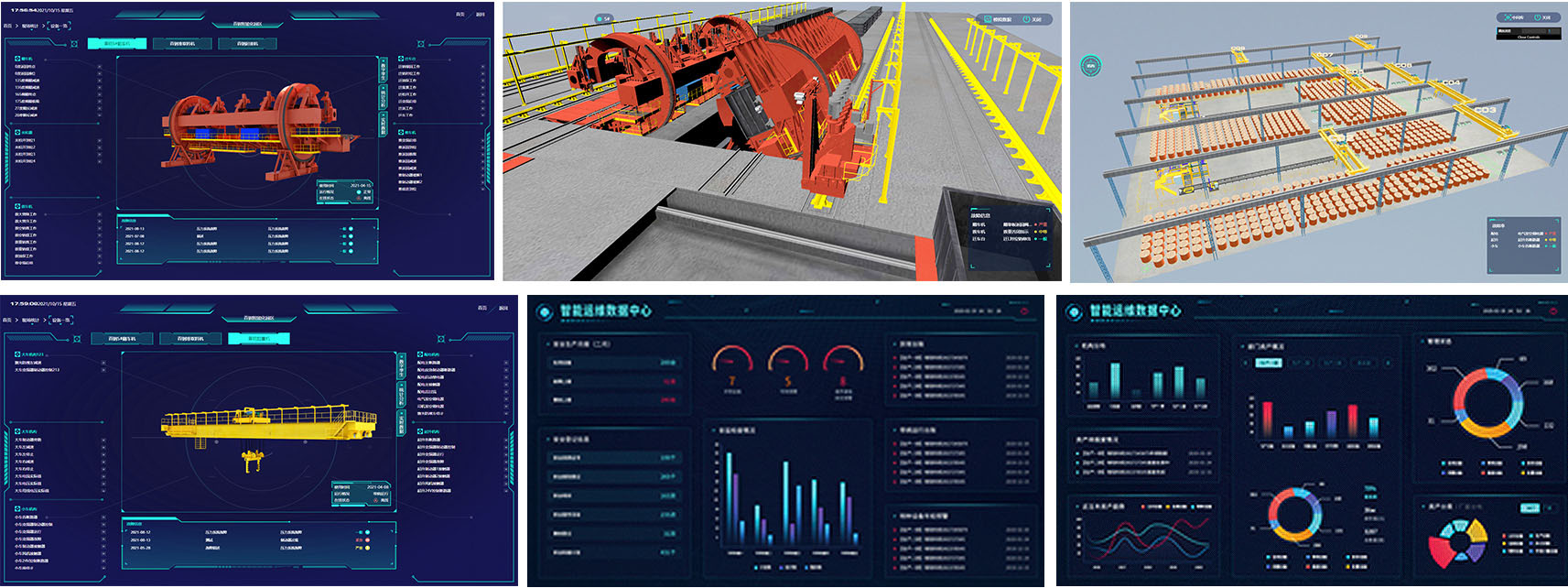

Intelligent total solution for remote operation and maintenance

Based on data analysis, HDM developed a remote intelligent operation and maintenance platform tailored to product performance and technical characteristics. This platform integrates currently prevailing advanced technologies such as fault diagnosis, sensor detection, digital twin technology, data analysis, data mining algorithms, and cloud computing. It enables functions such as fault location, maintenance plan suggestions, and more. This system has been successfully applied to various equipment, including coke oven machinery, stackers and reclaimers, cranes, continuous ship unloaders, and submerged arc furnaces.

The functions of fault location, maintenance plan recommendations, and other features are achieved through data analysis. This system integrates currently prevailing advanced technologies such as fault diagnosis, sensor detection, digital twin technology, data analysis, data mining algorithms, and cloud computing. It addresses the current extensive operation and maintenance needs of heavy machinery to achieve scientific operation, targeted inspections, precise maintenance, reduced maintenance costs, minimized downtime, and extended overall equipment lifespan.