Intelligent total solution for bulk material

The total solution for bulk cargo at intelligent ports and terminals is central to HDM’s customer service. This solution focuses on providing digitalized and intelligent products and services for the storage and transport of bulk materials at open/closed strip-shaped stockyards, circular yards, and terminals. The product range includes unmanned car dumpers, belt conveyors, stackers and reclaimers (boom type, scraper type, gantry type, and blending type), material unloading cars, ship loaders, and ship unloaders, as well as digitalized port and stockyard systems and remote operation and maintenance systems, all based on unmanned operation of the equipment.

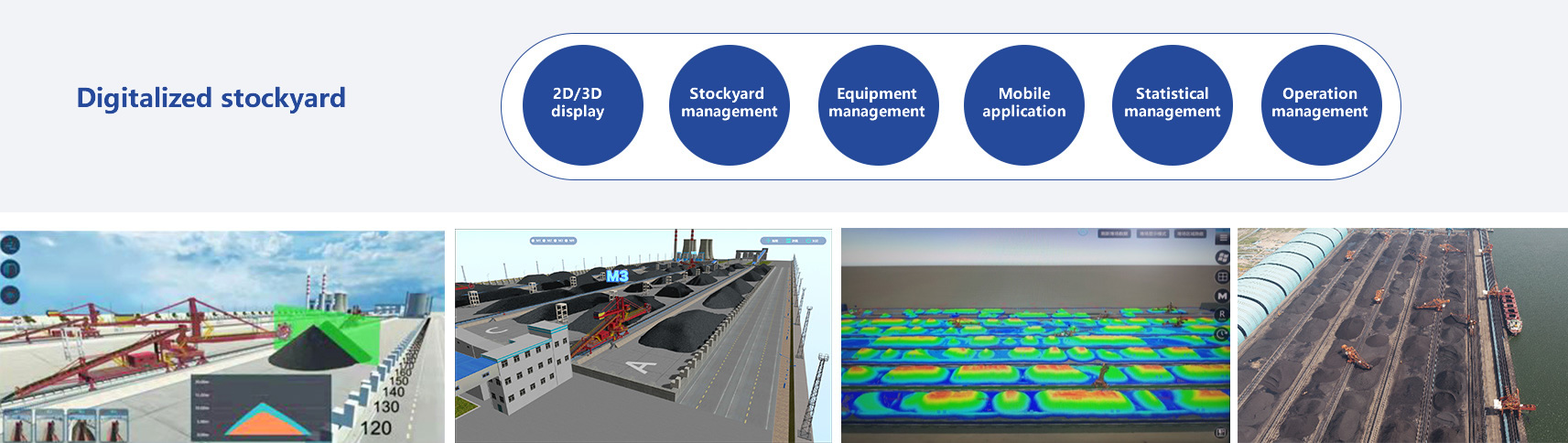

Digitalized stockyard system

Real-time information display functions for management, dispatching, and scheduling, based on data processing technology, aim to achieve unified scheduling management of infrastructure and improve overall efficiency in the stockyard flow.

Utilizing big data analysis technology helps achieve the industrial goal of normalized management and scientific production.

3D modeling technology makes management control intuitive and easy to operate, enhancing user experience and operational effectiveness.

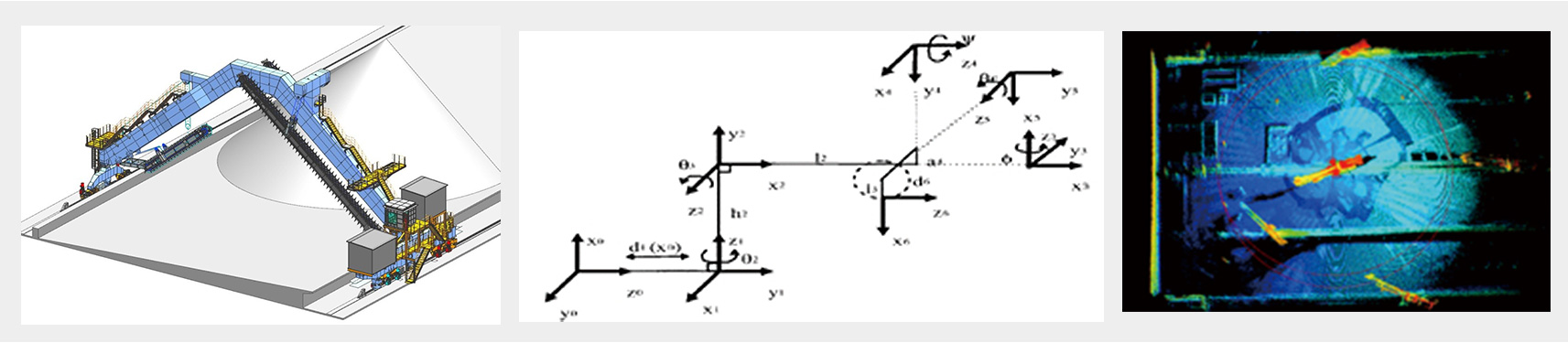

Unmanned system for stockyard equipment

The unmanned system for stackers and reclaimers is integrated with information technologies for equipment control, including machine vision technology, robust modeling technology, 3D image modeling technology, high-accuracy spotting technology, and anti-collision technology. By combining anti-collision technologies at both the data model level and the hardware detection level, stable material flow, safety, and high efficiency are achieved during machine operation.

Characteristics: Real-time collection of operational data, analysis of working schedules, integrated with dynamic stock data and other production management information. It provides functions such as equipment state analysis, production efficiency analysis, and resource utilization analysis for customers.

Advantage: A visualized panel fully displays production data and real-time status of the stockyard, along with the generation of reports. Annual labor cost savings (including other costs) exceed 1 million RMB for a single stacker and reclaimer. The total cost savings (including system life extension, energy savings, etc.) amount to 6.9 million RMB per year for twelve unmanned pieces of equipment, with equipment stability exceeding 80%.

Intelligent continuous ship unloader

This system integrates functions such as ship-type scanning and real-time imaging, multiple ship-type positioning and identification, intelligent decision-making for reclaiming from the hold, and 3D visualized scene restoration. The identification algorithm is more universal compared to other bulk cargo ships. Based on kinematic models and finite element models, the decision-making and analysis system incorporates dozens of reclaiming strategies, forming a multi-target optimized reclaiming strategy with an intelligent reclaiming coverage rate in the hold exceeding 80%. Additionally, the VR simulation platform enables virtual simulations, significantly reducing site commissioning time.

Effect: Compared to grab ship unloaders with the same productivity, this system increases efficiency by 50%, reduces energy consumption by 40%, and the hold clearing volume accounts for only 5% to 10%. Assuming an annual unloading volume of 10 million tons, it is expected to generate benefits of 10 million RMB for the terminal each year. Furthermore, the equipment operates more stably and is more environmentally friendly, reducing impact loads and extending equipment life, thus saving a significant amount of labor costs for customers.